Product Design & Development

Creating the visual concept and functional specifications of the uniform.

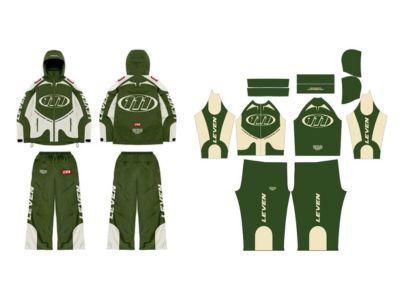

CAD Design (2D/3D) – Digital tools to develop artwork, patterns, and 3D visualizations.

Tech Pack Creation – Detailed document containing measurements, fabrics, colors, trims, and stitching specs.

Prototype & Sampling – Making sample uniforms to test fit, comfort, and overall design accuracy.

Fabric & Material Selection

Choosing performance materials suitable for specific sports.

Performance Fabrics (Polyester, Spandex, Mesh) – Moisture-wicking, stretchable, breathable fabrics.

Fabric Testing (Colorfastness, Stretch, Durability) – Ensures the materials withstand game conditions.

Sustainable Fabric Options – Recycled polyester, eco-dyes, and low-impact finishing processes.

Pattern Making & Grading

Converting the design into precise garment templates for all sizes.

Digital Pattern Making (CAD/CAM) – Accurate templates created using specialized software.

Manual Pattern Drafting – Traditional paper-based patterns for custom or small-batch needs.

Size Grading – Scaling the base pattern to all required sizes (XS–XXXL).

Printing & Decoration

Adding colors, logos, numbers, names, and team graphics.

Dye Sublimation Printing – All-over vibrant prints fused into polyester fabrics.

Screen Printing – Durable ink application for large logos and numbers.

Heat Transfer / Vinyl Names & Numbers – Personalized names and numbers pressed onto the fabric.

Embroidery / Patches – Premium crests, logos, and badges stitched or applied.

Fabric Cutting

Cutting fabric pieces according to approved patterns.

Manual Cutting – Hand cutting using rotary cutters for samples and small runs.

Automated Cutting (Laser / CNC / CAM Cutting) – High-speed, precise cutting for bulk production.

Marker Making & Fabric Layering – Optimizing fabric layout to reduce waste and improve efficiency.

Sewing & Assembly

Joining all fabric pieces to build the complete uniform.

Overlock Stitching (Serging) – Strong edge seams for athletic movements.

Flatlock Stitching – Flat, skin-friendly seams to reduce chafing.

Coverstitch Hems – Stretchable hems for sleeves and waistbands.

Lockstitch Construction – Clean seams for panels and finishing details.

Ultrasonic Bonding (High-Tech) – Seamless joining for lightweight, premium sportswear.

Bartack Reinforcement – Strengthening stress points like pockets or panel joints.

Quality Control (QC)

Ensuring each uniform meets quality, sizing, and safety standards.

Fabric & Trim Inspection – Checking input materials before production.

In-Line QC Checks – Monitoring stitching, alignment, and accuracy during sewing.

Final AQL Inspection – Measurement checks, color checks, and defect inspection before packing.

Functional Testing – Stretch, seam strength, and wash tests for durability.

Finishing & Packaging

Final steps before shipping the uniforms to the customer.

Thread Trimming & Cleaning – Removing loose threads and ensuring a clean finish.

Pressing / Steaming – Removing wrinkles and shaping the uniform.

Labeling & Tagging – Adding size tags, care labels, and branding.

Folding & Polybag Packing – Neat packing to protect the garment during transit.

Carton Packing & Shipping – Sorting by size, style, and order for dispatch.